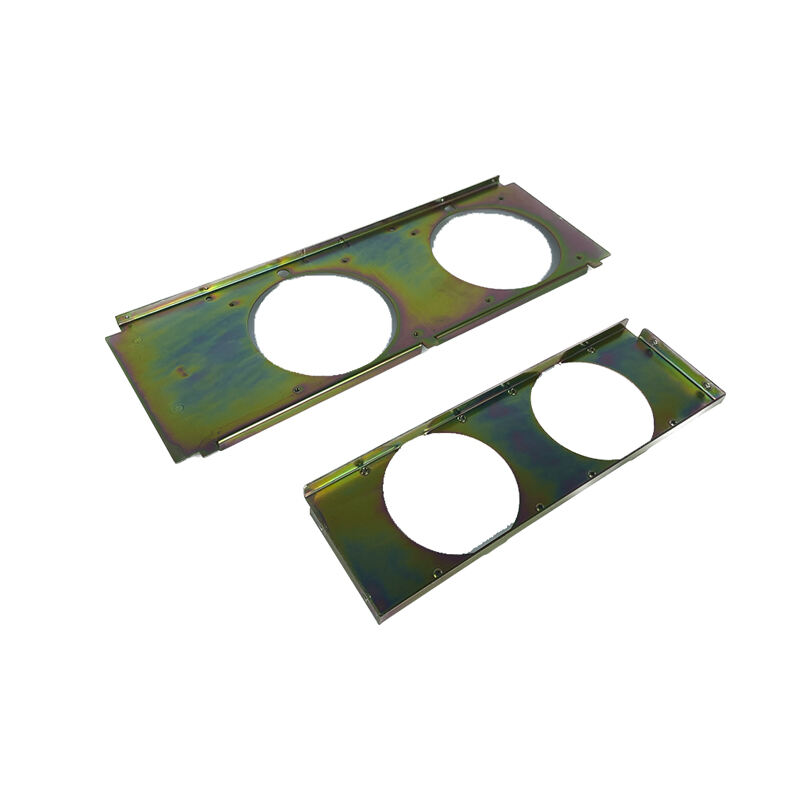

metal stamping services

Metal stamping services represent a sophisticated manufacturing process that transforms flat metal sheets into specific shapes through mechanical deformation. This versatile technique employs specialized tools and dies to create precise components for various industries. The process incorporates advanced technologies including progressive die stamping, transfer stamping, and four-slide stamping, each offering unique capabilities for different production requirements. Modern metal stamping services utilize computer-controlled systems and automated technology to ensure consistent quality and high precision in every component produced. The process can handle various materials including steel, aluminum, copper, and brass, with thickness ranges from thin gauges to several millimeters. These services are essential in producing components for automotive parts, electronics housings, aerospace components, and consumer goods. The technology allows for both simple and complex geometries, incorporating features such as bends, holes, embossments, and intricate patterns. Metal stamping services also offer secondary operations including finishing, plating, heat treating, and assembly to provide complete manufacturing solutions. The process is particularly valuable for high-volume production runs, offering cost-effective solutions while maintaining tight tolerances and exceptional quality standards.