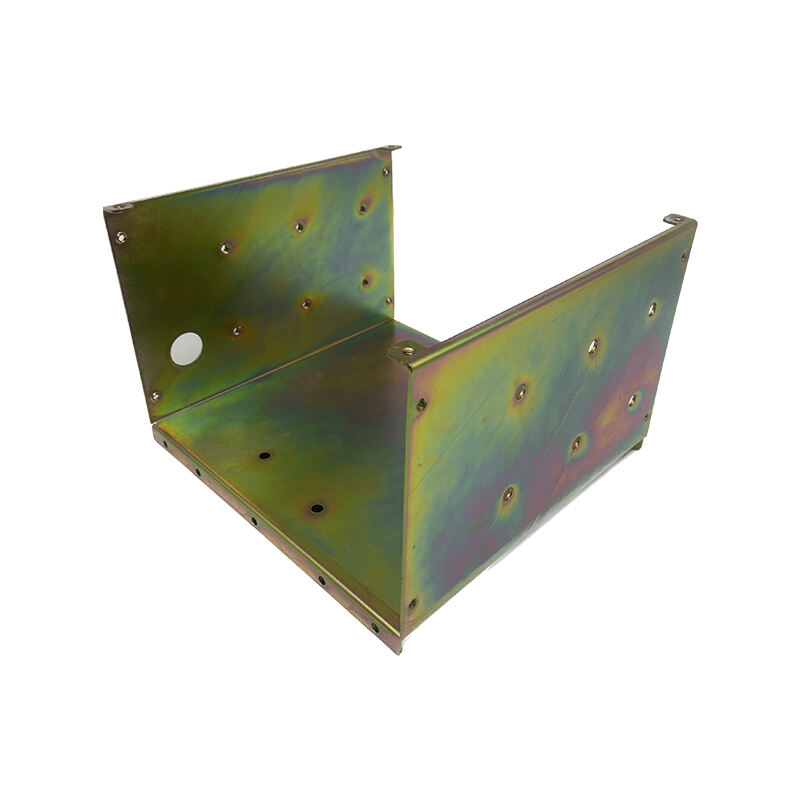

precision metal stamping

Precision metal stamping is a sophisticated manufacturing process that transforms flat metal sheets into specific components through controlled force application. This advanced technique combines high-speed automation with exceptional accuracy to produce complex metal parts across various industries. The process utilizes specialized tools and dies mounted in precision presses that can exert forces ranging from a few tons to several hundred tons. Modern precision stamping incorporates computer-controlled systems and advanced monitoring equipment to maintain tight tolerances, often achieving accuracies within 0.001 inches. The technology employs progressive dies, which perform multiple operations in sequence, including cutting, bending, forming, and piercing, all in a single production run. This manufacturing method is particularly valuable for producing high-volume components while maintaining consistent quality and dimensional stability. The versatility of precision stamping allows for processing various metals, including steel, aluminum, copper, and brass, making it indispensable in electronics, automotive, aerospace, and medical device manufacturing.