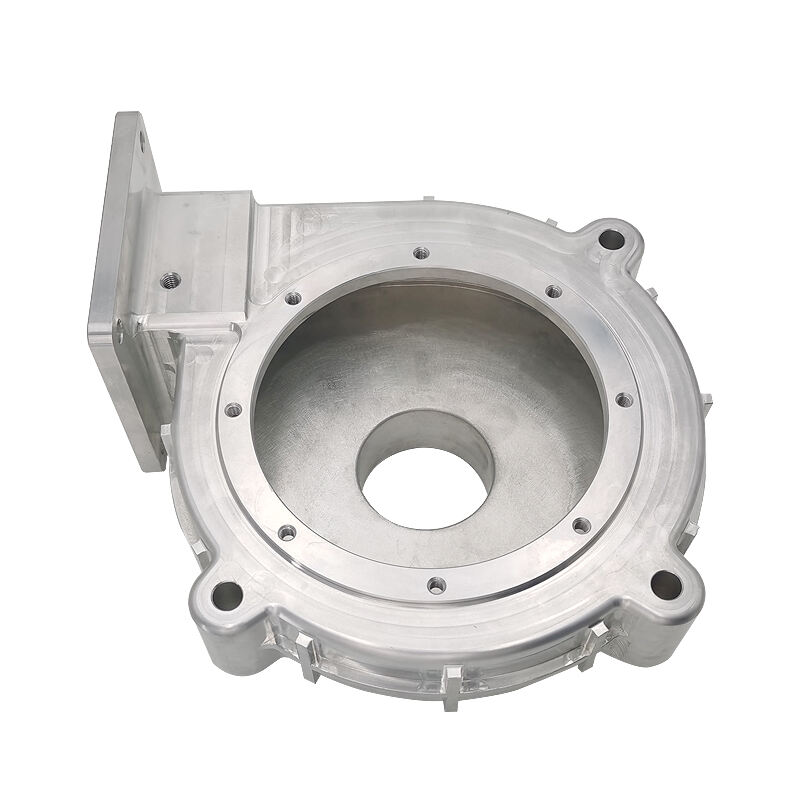

cnc aluminum part

CNC aluminum parts represent the pinnacle of precision manufacturing in modern industrial applications. These components are crafted through computer numerical control machining processes, utilizing high-grade aluminum alloys to create intricate and highly accurate parts. The manufacturing process involves sophisticated computer-controlled cutting tools that precisely remove material from aluminum blocks to achieve complex geometries and tight tolerances. These parts are distinguished by their exceptional dimensional accuracy, superior surface finish, and remarkable consistency across production runs. The versatility of CNC aluminum parts makes them indispensable in various industries, from aerospace and automotive to medical equipment and consumer electronics. They excel in applications requiring lightweight yet durable components, offering excellent thermal conductivity and corrosion resistance. The ability to produce these parts with intricate details and maintaining strict quality standards makes them ideal for both prototype development and mass production scenarios. Furthermore, CNC aluminum parts can be customized to meet specific requirements, incorporating features such as threaded holes, precise channels, and complex curved surfaces, all while maintaining structural integrity and dimensional stability.