aluminum machining

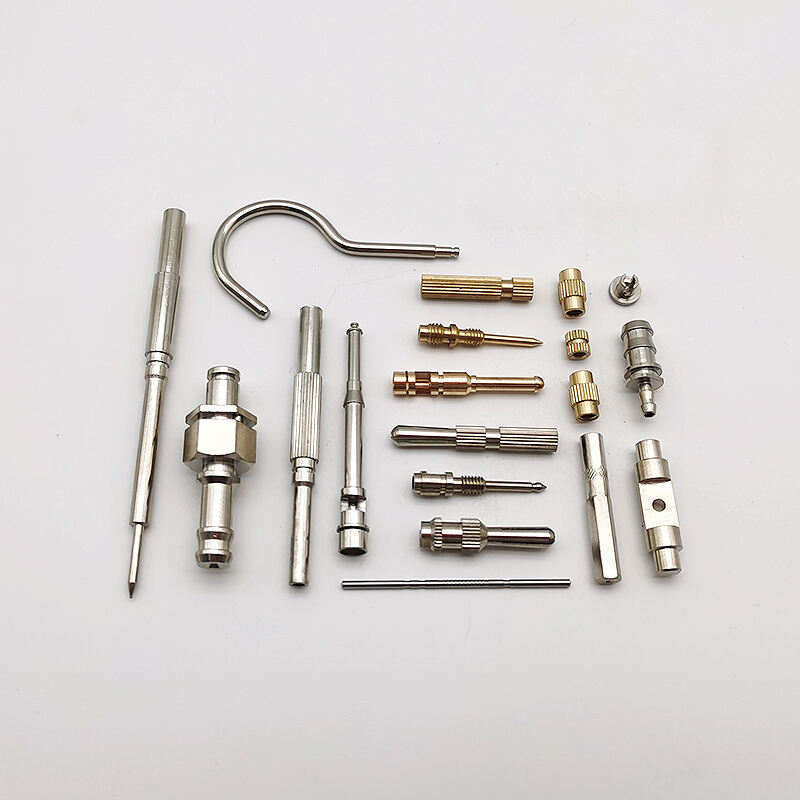

Aluminum machining is a sophisticated manufacturing process that transforms raw aluminum materials into precisely engineered components through various cutting, drilling, and shaping operations. This versatile process employs advanced CNC machinery and cutting-edge tools to achieve exceptional accuracy and consistency in production. The process encompasses multiple techniques including milling, turning, boring, and threading, allowing for the creation of complex geometries and tight tolerances. Modern aluminum machining centers can operate on multiple axes simultaneously, enabling the production of intricate parts with superior surface finishes. The technology incorporates advanced cooling systems and specialized cutting tools designed specifically for aluminum's unique properties, ensuring optimal material removal rates while maintaining dimensional stability. This manufacturing method is particularly valued in industries requiring lightweight, durable components, such as aerospace, automotive, and electronics. The process can handle various aluminum alloys, each selected based on specific application requirements, whether it's for structural components, decorative elements, or precision mechanical parts. With the integration of digital manufacturing technologies, aluminum machining has evolved to offer unprecedented levels of automation, quality control, and production efficiency.