Metal stamping has revolutionized modern manufacturing by enabling the production of precise, cost-effective components across countless industries. The success of any stamping operation fundamentally depends on selecting the appropriate material that balances mechanical properties, formability, and economic considerations. Understanding which materials perform best in metal stamping applications requires examining their unique characteristics, processing requirements, and end-use performance criteria.

The material selection process directly impacts tooling design, production efficiency, and final component quality. Engineers must evaluate factors including strength-to-weight ratios, corrosion resistance, electrical conductivity, and thermal properties when determining optimal materials for specific applications. Modern stamping operations rely on advanced metallurgy and material science to push the boundaries of what traditional forming processes can achieve.

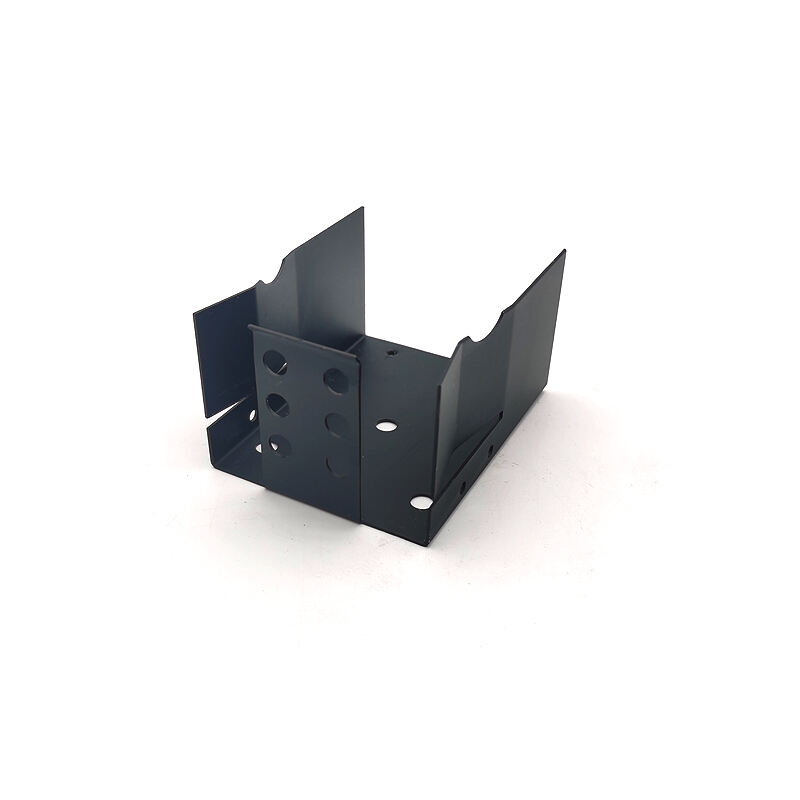

Low carbon steel remains one of the most versatile and widely used materials in metal stamping operations due to its exceptional formability and cost-effectiveness. With carbon content typically below 0.25%, these steels offer excellent ductility that allows for complex forming operations without cracking or tearing. The material's ability to undergo deep drawing, bending, and complex geometrical changes makes it ideal for automotive body panels, appliance housings, and structural components.

The work-hardening characteristics of low carbon steel provide additional benefits during stamping processes. As the material deforms, it gains strength while maintaining sufficient ductility for continued forming operations. This property enables manufacturers to create components with varying thickness requirements and complex geometries that would be difficult to achieve with higher carbon content steels. Cold-rolled variants offer superior surface finish and dimensional accuracy compared to hot-rolled alternatives.

High strength steels present unique opportunities and challenges in stamping applications. These materials, including advanced high-strength steels and ultra-high-strength variants, offer superior strength-to-weight ratios that enable lightweighting initiatives across automotive and aerospace sectors. However, their increased strength requires specialized tooling designs and enhanced press capabilities to achieve successful forming operations.

The springback characteristics of high strength steels demand careful consideration during tool design and process development. Manufacturers must account for elastic recovery after forming, often requiring overbending techniques or specialized compensation strategies. Despite these challenges, the weight reduction and performance benefits make high strength steels increasingly attractive for structural applications where strength and durability are paramount.

Aluminum alloys have gained significant traction in stamping applications due to their excellent strength-to-weight ratio and superior corrosion resistance properties. The 1000, 3000, and 5000 series aluminum alloys demonstrate particularly good formability characteristics that make them suitable for complex stamping operations. These alloys maintain their ductility at room temperature while offering sufficient strength for structural applications.

The work-hardening behavior of aluminum differs significantly from steel, requiring adjusted processing parameters and tooling considerations. Aluminum's tendency to gall or stick to tooling surfaces necessitates specialized lubricants and surface treatments to achieve consistent results. Despite these considerations, aluminum's recyclability and lightweight properties make it increasingly popular for automotive, aerospace, and consumer electronics applications.

Heat treatment conditions significantly influence the stampability of aluminum alloys. Annealed tempers provide maximum formability but reduced strength, while harder tempers offer increased strength at the expense of formability. Understanding these relationships allows engineers to select optimal material conditions that balance forming requirements with final component performance specifications.

Solution heat treatment and artificial aging can be strategically employed to achieve desired mechanical properties after forming operations. This approach enables manufacturers to form components in softer conditions and subsequently heat treat to achieve final strength requirements. The timing and temperature control during these processes critically impact final component quality and dimensional stability.

Copper and its alloys occupy a unique position in stamping applications where electrical conductivity is paramount. Pure copper offers the highest conductivity but presents formability challenges due to its tendency to work-harden rapidly. Brass alloys, particularly those in the 260 and 360 compositions, provide excellent stampability while maintaining good electrical properties for connector and switch applications.

The antimicrobial properties of copper alloys have created new opportunities in medical device and food processing equipment manufacturing. These materials require specialized handling and processing techniques to prevent contamination and maintain surface quality. Metal stamping parts made from copper alloys often require post-processing treatments to achieve desired surface finishes and conductivity specifications.

Copper-based alloys demonstrate exceptional corrosion resistance in marine and harsh environmental conditions. Bronze and brass compositions offer varying degrees of strength and corrosion resistance that can be tailored to specific application requirements. The natural patina formation on copper alloys provides long-term protection against atmospheric corrosion without compromising structural integrity.

Naval brass and aluminum bronze represent premium materials for marine stamping applications where both strength and corrosion resistance are critical. These materials require careful temperature control during forming operations to prevent cracking and maintain optimal mechanical properties. The investment in specialized tooling and processing techniques is often justified by the superior long-term performance in demanding environments.

Austenitic stainless steels, particularly grades 304 and 316, represent the most commonly stamped stainless steel variants due to their excellent formability and corrosion resistance. These materials maintain their austenitic structure at room temperature, providing superior ductility compared to ferritic or martensitic grades. The work-hardening characteristics of austenitic steels can be both beneficial and challenging depending on the complexity of forming operations.

The higher strength levels of stainless steel require increased forming forces and specialized tooling materials to prevent galling and excessive wear. Surface treatments and lubricants play critical roles in achieving consistent results while maintaining the corrosion-resistant properties that make stainless steel attractive. The material's tendency to springback requires careful compensation in tooling design and process parameters.

Duplex and super-duplex stainless steels offer enhanced strength and corrosion resistance but present significant stamping challenges due to their two-phase microstructure. These materials require elevated forming temperatures and specialized processing techniques to achieve acceptable formability. The investment in enhanced capabilities is often justified by superior performance in chemical processing and offshore applications.

Precipitation-hardening stainless steels enable unique processing strategies where components are formed in solution-treated conditions and subsequently aged to achieve final strength requirements. This approach allows complex geometries to be formed with minimal springback concerns while delivering exceptional final mechanical properties. The timing and temperature control during aging operations critically impact dimensional stability and performance characteristics.

Titanium alloys represent the frontier of advanced stamping applications where exceptional strength-to-weight ratios and corrosion resistance justify premium material costs. Grade 2 commercially pure titanium offers the best formability among titanium variants, enabling complex geometries for aerospace and medical applications. The material's tendency to react with oxygen at elevated temperatures requires specialized atmospheric controls during forming operations.

Alpha-beta titanium alloys such as Ti-6Al-4V provide enhanced strength properties but require elevated forming temperatures to achieve acceptable formability. Hot stamping techniques enable the production of complex components that would be impossible to form at room temperature. The investment in specialized equipment and atmospheres is often justified by the superior performance characteristics and weight savings achieved in critical applications.

Metal matrix composites and hybrid material systems are beginning to find applications in specialized stamping operations. These materials combine the formability of metal matrices with enhanced properties from ceramic or fiber reinforcements. Processing these materials requires careful attention to reinforcement orientation and distribution to maintain structural integrity during forming operations.

Shape memory alloys and smart materials represent emerging opportunities for stamping applications where active response to environmental conditions is desired. These materials require specialized processing techniques to maintain their unique properties while achieving required geometrical configurations. The integration of smart materials into traditional stamping processes opens new possibilities for adaptive and responsive component designs.

Material selection depends on multiple factors including required mechanical properties, formability characteristics, corrosion resistance, electrical conductivity, cost constraints, and end-use environmental conditions. Engineers must balance these requirements with available processing capabilities and tooling investments to achieve optimal results.

Material thickness directly impacts forming forces, springback characteristics, and achievable detail resolution in stamped components. Thicker materials generally require higher forming forces and may limit geometric complexity, while thinner materials offer enhanced formability but may present handling and dimensional stability challenges during processing.

While challenging, dissimilar materials can sometimes be processed together using specialized techniques such as insert molding or progressive assembly operations. However, differences in material properties often require separate processing steps and joining operations to achieve successful multi-material components.

Surface finish requirements significantly influence material selection and processing parameters. Materials requiring maintained surface quality may need specialized lubricants, tooling materials, and handling procedures to prevent scratching or marking during forming operations. Pre-coated materials often provide superior final appearance but may require modified processing techniques.