Manufacturing companies across various industries are constantly seeking innovative ways to reduce production costs while maintaining superior quality standards. Among the most effective solutions available today, metal stamping parts have emerged as a cornerstone technology that delivers exceptional cost savings through streamlined processes, material efficiency, and scalable production capabilities. This manufacturing technique transforms flat metal sheets into precise components through specialized dies and presses, creating parts that meet exact specifications while significantly reducing per-unit costs compared to traditional machining methods.

The economic benefits of metal stamping parts become increasingly apparent as production volumes scale upward. Unlike machining processes that require individual attention for each component, stamping operations can produce thousands of identical parts per hour once the initial tooling is established. This rapid production capability dramatically reduces labor costs per unit, as a single operator can oversee multiple stamping presses simultaneously. The automated nature of modern stamping equipment further enhances this efficiency by minimizing human intervention and reducing the likelihood of costly production errors.

Manufacturing facilities implementing metal stamping solutions typically observe cost reductions of thirty to fifty percent when transitioning from traditional machining methods. These savings stem from reduced cycle times, lower labor requirements, and improved material utilization rates. The consistent repeatability of stamped components also eliminates the need for extensive quality control measures, as properly designed dies produce parts within tight tolerances automatically.

Efficient material usage represents another significant cost advantage associated with metal stamping parts production. Advanced nesting software optimizes part layouts on metal coils or sheets, maximizing material utilization while minimizing waste. This optimization process can achieve material efficiency rates exceeding ninety percent, compared to traditional machining methods that often waste substantial amounts of raw material through cutting and drilling operations.

The precision of modern stamping dies ensures that material thickness remains consistent throughout the forming process, eliminating the need for additional material allowances typically required in other manufacturing methods. Furthermore, the metal removed during blanking and piercing operations can often be recycled or used for smaller components, creating additional value from what would otherwise be considered waste material.

While the initial investment in stamping dies may appear substantial, the long-term cost benefits far outweigh this upfront expense for medium to high-volume production runs. Progressive dies, in particular, offer exceptional value by combining multiple forming operations into a single press stroke, eliminating the need for separate machining setups and reducing handling time between operations. The durability of properly maintained stamping dies allows for millions of parts to be produced before requiring replacement or refurbishment.

Modern die design incorporates advanced materials and surface treatments that extend tool life significantly beyond traditional options. Carbide inserts, specialized coatings, and precision heat treatment processes ensure that dies maintain their dimensional accuracy throughout extended production runs. This longevity translates directly into lower per-unit tooling costs as the initial investment is amortized across larger quantities of produced parts.

The maintenance requirements for metal stamping equipment are generally lower than those associated with complex machining centers or multi-axis manufacturing systems. Stamping presses feature robust construction designed for continuous operation, with predictable maintenance schedules that allow for planned downtime rather than unexpected production interruptions. Regular maintenance activities such as lubrication, die inspection, and press calibration can be performed quickly without extensive disassembly or specialized technical expertise.

Preventive maintenance programs for stamping operations typically result in equipment availability rates exceeding ninety-five percent, ensuring consistent production output and delivery schedules. The simplicity of stamping press operation also reduces training requirements for manufacturing personnel, leading to lower labor costs and faster employee onboarding processes.

Metal stamping parts exhibit exceptional dimensional consistency that eliminates the need for costly secondary machining operations in many applications. Modern stamping dies can achieve tolerances within plus or minus 0.002 inches for critical dimensions, matching or exceeding the accuracy of traditional machining methods while operating at significantly higher production speeds. This precision stems from the rigid nature of stamping dies and the controlled force application during the forming process.

The repeatability of stamped components reduces variation in assembly processes, leading to improved product quality and reduced warranty claims. Consistent part dimensions ensure proper fit and function in complex assemblies, eliminating the need for selective assembly techniques or post-production adjustments that add time and cost to manufacturing operations.

Stamping operations can incorporate surface treatments and coatings directly into the production process, eliminating separate finishing operations that would otherwise increase manufacturing costs. Pre-coated materials such as galvanized steel or aluminum alloys with protective finishes can be stamped without damaging the surface treatment, provided that die design and lubrication systems are properly optimized for these materials.

The smooth surface finish achieved through proper stamping techniques often meets final product requirements without additional polishing or texturing operations. This capability is particularly valuable in applications where appearance quality is important, as it eliminates the cost and time associated with secondary finishing processes while maintaining consistent visual standards across all produced parts.

Modern metal stamping operations integrate seamlessly with robotic automation systems that further reduce labor costs and improve production efficiency. Automated material handling systems can feed raw material coils, position blanks for stamping, and transfer finished parts to packaging or assembly areas without human intervention. These systems operate continuously during production shifts, maximizing equipment utilization while minimizing labor requirements.

The integration of vision systems and quality sensors within automated stamping lines enables real-time quality monitoring and automatic rejection of non-conforming parts. This capability eliminates the need for dedicated quality control personnel while ensuring that only acceptable metal stamping parts proceed to subsequent assembly operations, reducing downstream costs associated with defective components.

The predictable nature of metal stamping operations simplifies production planning and scheduling activities, reducing administrative overhead costs associated with complex manufacturing systems. Stamping press cycle times are highly consistent and easily calculated, allowing for accurate delivery commitments and efficient resource allocation. This predictability enables lean manufacturing principles such as just-in-time production, which reduces inventory carrying costs and improves cash flow.

Quick die change systems available on modern stamping presses minimize setup time between different part numbers, enabling efficient small-batch production runs when required. These systems can reduce changeover times from hours to minutes, making it economically feasible to produce smaller quantities of specialized components without significant cost penalties.

The automotive industry has extensively adopted metal stamping parts to achieve the cost targets necessary for competitive vehicle pricing. Body panels, structural components, and interior hardware produced through stamping processes deliver the combination of strength, weight efficiency, and cost-effectiveness required for modern vehicle designs. The ability to form complex three-dimensional shapes in single operations eliminates welding and assembly steps that would otherwise add significant manufacturing costs.

Advanced high-strength steels commonly used in automotive applications are particularly well-suited for stamping operations, as the cold-forming process can actually improve material properties through work hardening effects. This characteristic allows automotive manufacturers to use thinner gauge materials while maintaining structural requirements, resulting in both material cost savings and improved fuel efficiency through weight reduction.

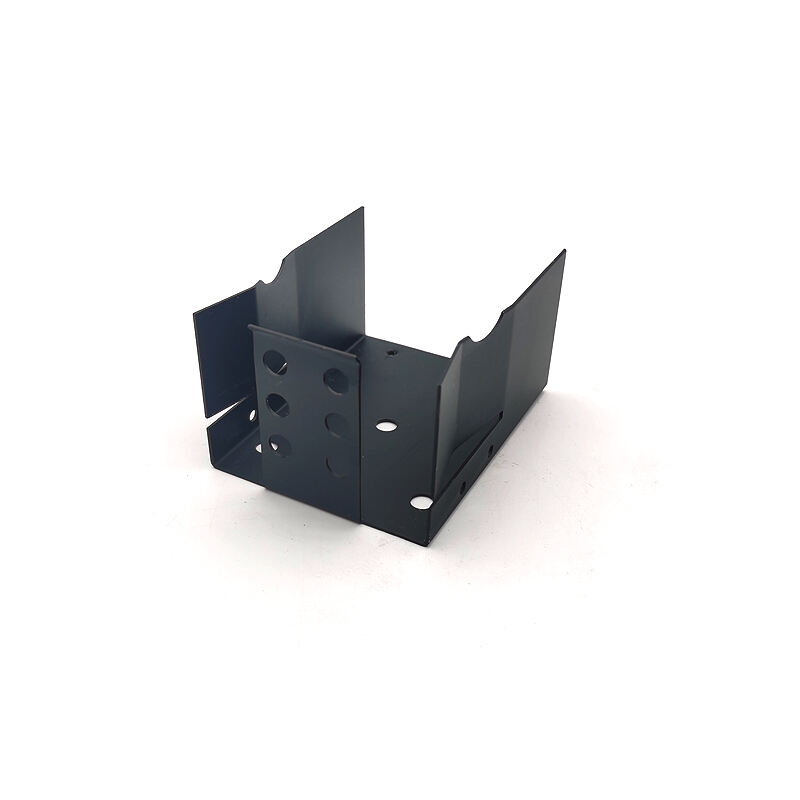

Consumer electronics and appliance manufacturers rely heavily on metal stamping parts to achieve the cost points necessary for mass-market products. The precision and consistency of stamped components are essential for electromagnetic shielding applications, where consistent gaps and contact surfaces are critical for proper function. The ability to integrate mounting features, cooling fins, and connector interfaces into single stamped parts eliminates assembly operations and reduces overall product costs.

The thin-gauge materials commonly used in electronics manufacturing are ideal candidates for stamping operations, as the process can handle materials as thin as 0.005 inches while maintaining dimensional accuracy. This capability enables the production of lightweight, cost-effective components that meet the demanding requirements of portable electronic devices and energy-efficient appliances.

Metal stamping parts typically become more cost-effective than machined alternatives at production volumes exceeding 1,000 pieces annually, though this threshold varies based on part complexity and material requirements. The breakeven point occurs when the amortized tooling costs combined with lower per-unit production expenses offset the higher initial die investment. For high-volume applications producing tens of thousands of parts, stamping can reduce costs by fifty percent or more compared to traditional machining methods.

Material selection significantly impacts the economic advantages of metal stamping parts, with softer materials like aluminum and low-carbon steel offering the greatest cost benefits due to reduced die wear and lower forming forces. Harder materials such as stainless steel or high-strength alloys may require more expensive tooling and slower production speeds, though they still typically provide cost advantages over machining for medium to high-volume applications. Pre-coated materials can eliminate secondary finishing operations, further enhancing cost effectiveness despite higher raw material prices.

Stamping die lifespan depends on material hardness, part complexity, production volume, and maintenance practices, with properly maintained dies producing anywhere from 100,000 to several million parts before requiring refurbishment. Progressive dies handling multiple operations simultaneously often provide better long-term value despite higher initial costs, as they eliminate handling between operations and reduce overall cycle times. Regular maintenance including proper lubrication, periodic sharpening, and dimensional inspection can extend die life significantly, reducing the amortized tooling cost per part.

Metal stamping parts offer superior cost efficiency compared to casting, forging, or machining for most applications requiring thin to medium-thickness components with moderate complexity. While casting may be more cost-effective for very complex three-dimensional shapes, stamping excels in producing flat or moderately formed parts with excellent surface finish and tight tolerances. Hydroforming and other specialized forming methods may offer advantages for specific applications, but stamping remains the most versatile and cost-effective solution for the majority of sheet metal component requirements across diverse industries.