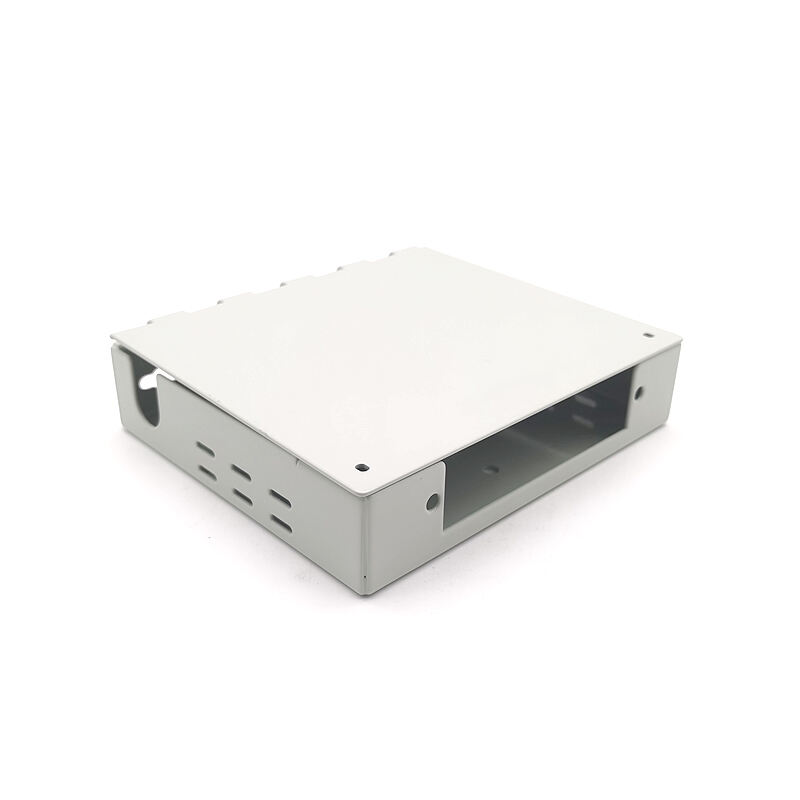

sheet metal box fabrication

Sheet metal box fabrication represents a crucial manufacturing process that transforms flat metal sheets into customized enclosures and containers through precise cutting, bending, and joining operations. This versatile fabrication method combines advanced technology with traditional metalworking techniques to create durable, functional boxes that serve various industrial and commercial purposes. The process typically begins with design specifications, followed by CNC-driven cutting and forming operations that ensure exact dimensions and tolerances. Modern sheet metal box fabrication employs sophisticated equipment including laser cutters, press brakes, and welding systems to achieve superior quality and consistency. These boxes can be manufactured using various materials such as stainless steel, aluminum, or galvanized steel, each offering specific advantages for different applications. The fabrication process allows for numerous customization options, including different sizes, shapes, mounting options, and surface finishes. Applications span across multiple industries, from electronics housing and electrical enclosures to HVAC systems and industrial machinery components. The precision of modern fabrication techniques ensures excellent fit and finish, while also maintaining structural integrity and environmental protection capabilities.