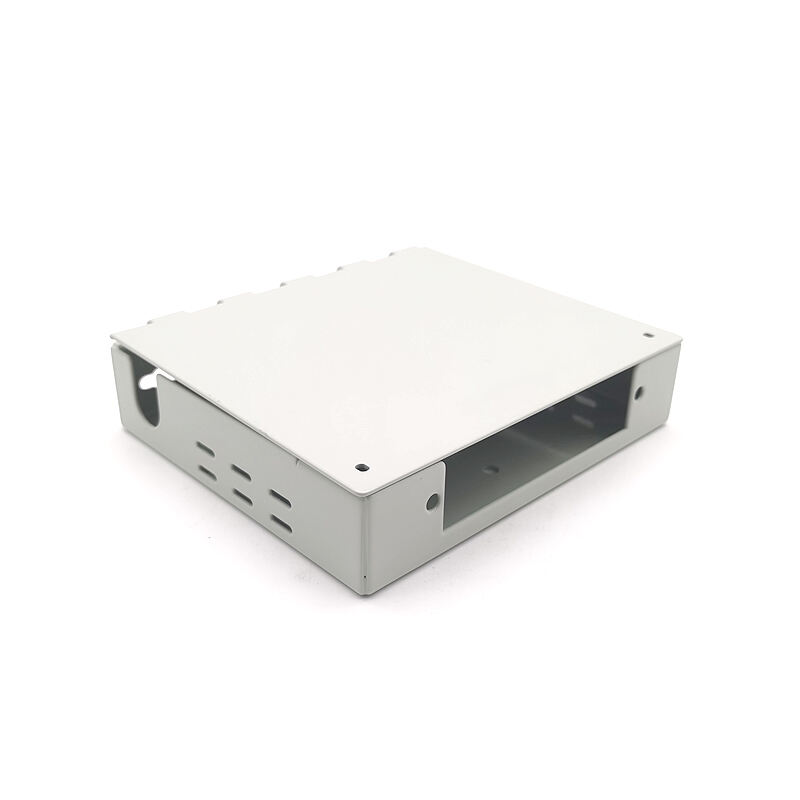

metal box fabrication

Metal box fabrication represents a crucial manufacturing process that combines precision engineering with industrial craftsmanship to create durable, customized storage and enclosure solutions. This sophisticated process encompasses various stages, including material selection, cutting, forming, welding, and finishing, all executed with meticulous attention to detail. Modern metal box fabrication employs advanced CNC machinery and automated systems to ensure consistent quality and dimensional accuracy. These fabricated boxes serve multiple purposes across industries, from housing sensitive electronic components to providing robust storage solutions for industrial applications. The process typically begins with premium-grade metals like steel, aluminum, or stainless steel, which are precisely cut and shaped according to specifications. Advanced techniques such as laser cutting and press brake forming enable the creation of complex designs with tight tolerances. Quality control measures are implemented throughout the fabrication process, including material testing, weld inspection, and dimensional verification. The finished products often feature additional elements such as gaskets, hinges, locks, and custom paint finishes to meet specific application requirements.