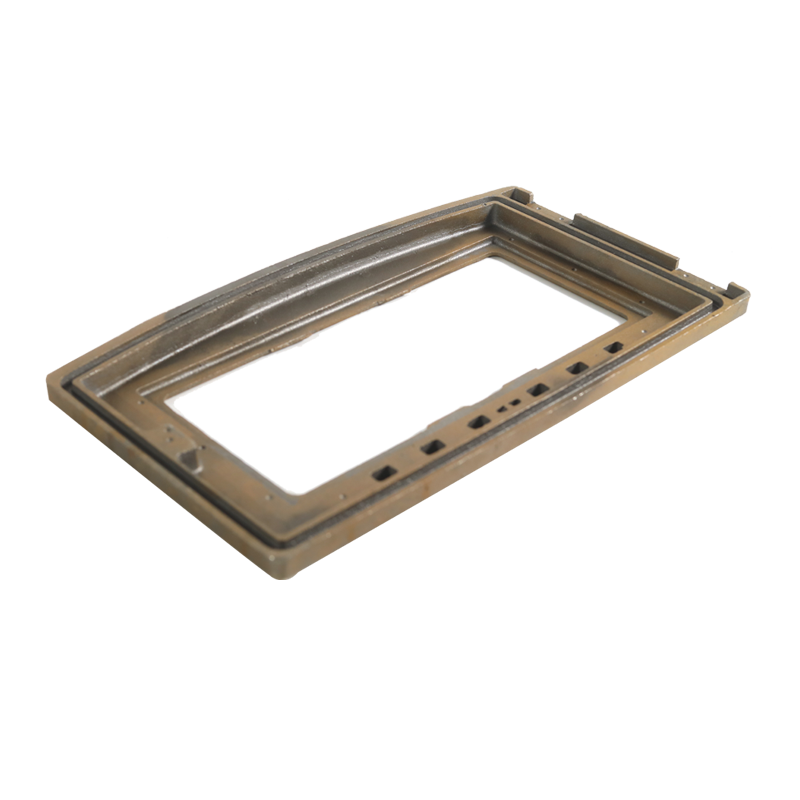

sand casting

Sand casting represents one of the most versatile and widely used manufacturing processes in metal forming. This time-tested method involves creating a mold from sand mixed with clay and other binding materials, into which molten metal is poured to create the desired part. The process begins with a pattern, typically made from wood, metal, or plastic, which is used to form the cavity in the sand mold. The mold consists of two halves, with the pattern impression creating the external shape of the casting. Additional features like cores can be inserted to form internal cavities. The sand mixture used is specially formulated to maintain its shape while allowing gases to escape during the pouring process, preventing defects in the final casting. Once the molten metal solidifies and cools, the sand mold is broken away to reveal the cast part. This process can accommodate a vast range of metals, from aluminum and brass to iron and steel, and can produce parts ranging from small components weighing a few ounces to massive industrial pieces weighing several tons. The versatility of sand casting makes it particularly valuable in industries such as automotive manufacturing, machinery production, and construction equipment fabrication.