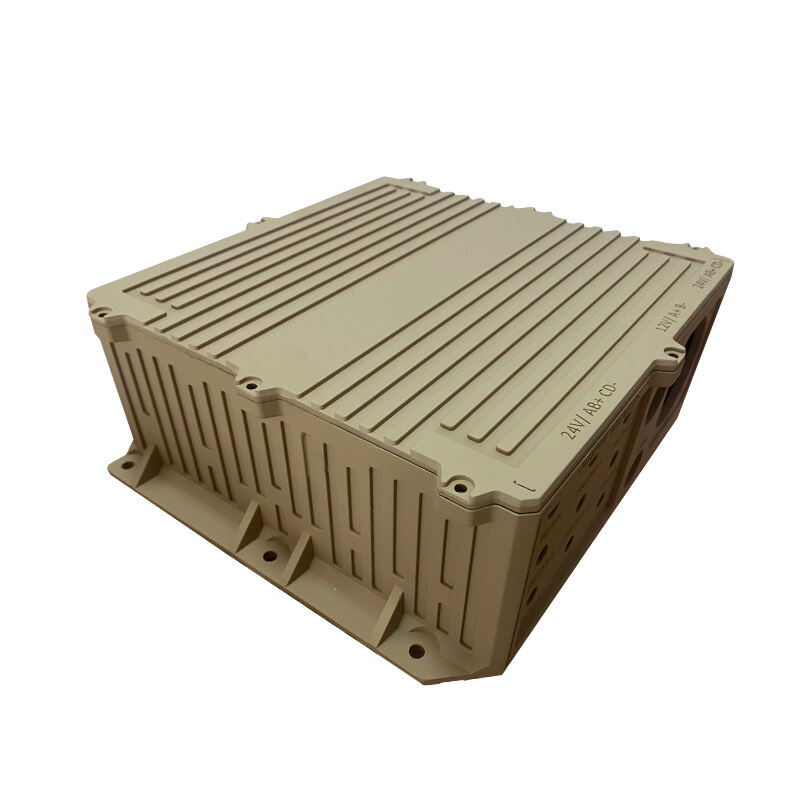

investment casting aluminum

Investment casting aluminum is a sophisticated manufacturing process that combines ancient casting techniques with modern metallurgical advances. This precision-based method involves creating a wax pattern of the desired component, which is then coated with ceramic material to form a mold. Once the wax is melted and removed, molten aluminum is poured into the cavity, resulting in highly accurate and complex parts. The process excels in producing components with intricate geometries, thin walls, and superior surface finishes that would be difficult or impossible to achieve through other manufacturing methods. Investment casting aluminum offers exceptional dimensional accuracy, typically achieving tolerances of ±0.005 inches or better, making it ideal for aerospace, automotive, and medical applications. The process allows for the creation of near-net-shape parts, minimizing the need for secondary machining operations and reducing material waste. Additionally, investment cast aluminum components exhibit excellent mechanical properties, including high strength-to-weight ratios, corrosion resistance, and uniform grain structure throughout the part.