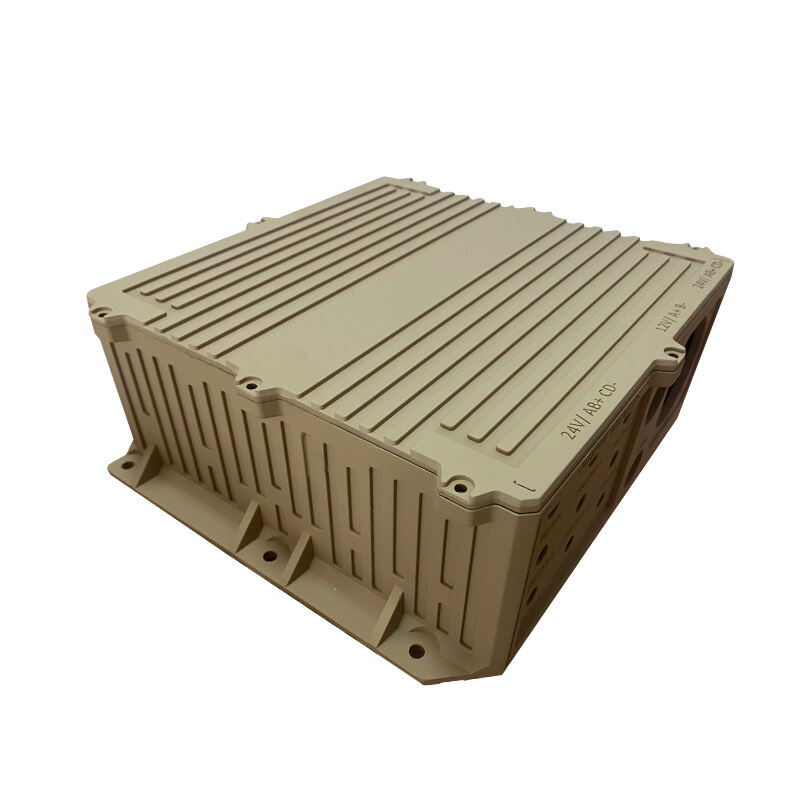

aluminum casting parts

Aluminum casting parts represent a cornerstone in modern manufacturing, offering an optimal blend of durability, versatility, and cost-effectiveness. These components are produced through various casting processes, including die casting, sand casting, and permanent mold casting, each method carefully selected based on specific application requirements. The process involves melting aluminum alloys and pouring them into precisely engineered molds, creating complex geometries and intricate designs that would be difficult or impossible to achieve through other manufacturing methods. These parts excel in applications requiring high strength-to-weight ratios, excellent thermal conductivity, and superior corrosion resistance. From automotive components to aerospace parts, aluminum castings are integral in industries where weight reduction and performance optimization are crucial. The manufacturing process allows for exceptional dimensional accuracy and surface finish, while also enabling the integration of various functional features such as internal channels, mounting points, and structural reinforcements. Modern aluminum casting techniques incorporate advanced simulation software and quality control measures, ensuring consistent product quality and reducing production costs through optimized material usage and enhanced process efficiency.