Custom dies are essential for creating detailed shapes that regular options just cant match. They really boost how well aluminum extrusion works because they let makers produce all sorts of complicated shapes and angles. When companies spend money on making their dies with super tight tolerances, they end up wasting way less material while getting things made faster. This saves cash and is better for the planet too. Most shops now rely heavily on computer aided design programs to get those dies right. According to industry reports, when these software tools are properly used, mistakes drop around 20 percent. That means products hit the market quicker without sacrificing quality, which everyone wants to see happen.

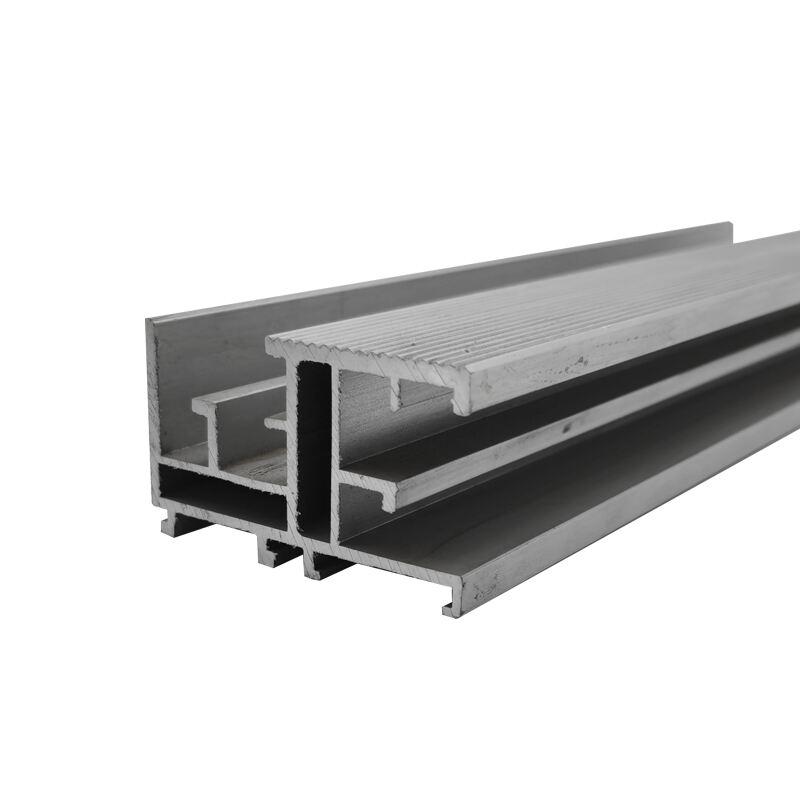

The decision between hollow versus solid extrusion setups really matters when it comes to what works best for specific applications and how much money gets spent. Hollow aluminum extrusions tend to be the go to option because they save weight and provide better thermal and sound insulation. These features make them great choices for things like building facades or transportation components where those benefits actually matter. Solid extrusions tell a different story though. They bring much stronger structural support which is exactly what's needed for structures that need to hold heavy loads without failing. Companies often find themselves saving quite a bit of cash when going with hollow options too. Some real world examples show material expenses dropping around 30% in certain cases. So this isn't just about technical specs either it affects how fast production moves along and ultimately determines whether a project stays within budget or goes over.

Manufacturers who switch to continuous profiles find all sorts of benefits for their operations. When companies incorporate these profiles into their production lines, they tend to see less material going to waste and lower energy bills overall, something that fits right into green manufacturing initiatives. The materials themselves have better strength characteristics too, meaning products last longer before needing replacement. Many plants that adopted continuous extrusion techniques report noticeable gains in output speed. Some factories claim production rates jumped by around 40%, though results vary depending on the setup. Beyond just making things faster, this kind of improvement actually helps bottom lines grow while keeping pace with competitors in the market.

Aluminum alloys really shine when it comes to strength versus weight, which is why so many industries rely on them for applications where performance matters but weight needs to stay low. These materials can actually reduce overall weight by around half compared to what we traditionally work with, while still keeping things running smoothly or sometimes even better across different settings. Getting the right type of aluminum alloy makes all the difference though. Manufacturers need to know exactly what they're working with because not every alloy behaves the same way under stress or heat conditions. Some might hold up great in aircraft parts but fail miserably in automotive components without proper selection.

Aluminum Extrusions have become a staple in the aerospace sector thanks to their combination of light weight and strength, which works really well for building aircraft frames. The parts made from these extrusions need to stand up to massive amounts of stress without failing, keeping planes safe even under tough conditions. Studies back up what engineers already know about these materials too. Some tests show that using better quality Aluminum Extrusions can cut down on weight by around 10%, which means planes burn less fuel during flights and put out fewer harmful emissions into the atmosphere. This makes them not just technically sound but environmentally responsible choices for modern aviation.

Lightweight aluminum in car construction makes a real difference when it comes to how efficiently vehicles use energy. Research shows cutting down a car's weight by about 10% can boost fuel economy somewhere between 6 and 8 percent. For drivers, this means spending less at the pump while also leaving behind fewer emissions, which explains why aluminum keeps getting attention as part of greener transport options. What's more, aluminum stands out because it can be recycled again and again without losing quality, making it a smart choice for manufacturers looking to cut waste and environmental harm across their production lines.

Aluminum extrusions are really important when it comes to managing heat in electronic enclosures. They can get rid of excess heat pretty well, which keeps electronic parts working properly without getting damaged. When manufacturers add things like fins or channels into the design, they actually help move air around better inside the enclosure. We've seen this work time and again where components don't overheat as much, so products last longer and perform more reliably overall. For companies looking to boost how their devices handle heat, aluminum extrusions have become a go to solution across many different industries dealing with thermal challenges.

Aluminum extrusions have really changed how buildings get put together these days because they make modular designs possible. With these systems, construction crews can assemble and take apart structures much quicker than traditional methods allow. The flexibility of such systems means architects can tweak designs on the fly to fit different site conditions or client demands, which is why many developers prefer them for contemporary building projects. Contractors report that using aluminum frames cuts down construction schedules somewhere around 20% give or take depending on the project specifics. This kind of adaptability makes sense both practically and economically since buildings need to serve multiple purposes over their lifespan while still looking good and functioning well according to whatever architectural vision was originally conceived.

Aluminum extrusions play a key role in making cars safer because they combine flexibility with solid strength. When car makers shape these aluminum parts just right, they actually help soak up energy from crashes, which means better protection for people inside when accidents happen. Crash tests show cars built with modern aluminum frames tend to get higher safety scores than older models without them. Beyond safety benefits, using aluminum lets designers make vehicles lighter without sacrificing structural integrity. Many automakers now rely on aluminum for everything from door frames to roof structures, proving why it remains central to developing vehicles that protect occupants while still meeting fuel efficiency standards demanded by today's market.

Anodizing helps make aluminum extrusions much more resistant to corrosion, so they last longer when exposed to tough environments. The process forms a protective oxide coating right on the metal's surface. This not only makes the aluminum stronger but also allows it to be colored in many different ways, which looks great for products that need to stand out visually. Research shows that properly treated aluminum can fight off rust and decay for around 30 years or so, though this depends heavily on what kind of weather and chemicals it faces daily. Because of how long it lasts and its good looks, anodized aluminum is especially popular for outdoor structures, architectural elements, and industrial components where strength meets style requirements.

CNC machining remains one of the best ways to get those super tight tolerances needed for aluminum parts, especially when quality matters most in fields such as aircraft manufacturing or medical device production. The machines can handle really complex shapes while keeping everything within spec, which means safer products and better overall performance from what comes off the line. Companies have found that switching to CNC tech keeps things accurate but cuts down on machining time somewhere around 20-25% give or take. That kind of improvement speeds up how fast they can produce goods and makes better use of their equipment, something manufacturers are definitely looking for these days when customers want both precision work and quicker turnaround times.

When it comes to Aluminum Extrusions, powder coating gives them a tough yet flexible finish that combines protection with lots of color and texture choices. The coating process really boosts how well Aluminum holds up on surfaces, standing strong against rough conditions without cracking or peeling easily. According to industry data, most powder coated Aluminum lasts around 15 years before showing signs of wear from chips or fading, which makes it pretty popular for jobs needing both good looks and lasting protection. Contractors love this stuff when appearance matters just as much as strength does, so we see it all over places like commercial buildings and outdoor furniture where things need to look great while handling whatever weather throws at them.

Digital simulations are changing the game when it comes to creating prototypes during the initial stages of product design. With these virtual models, designers can see their ideas take shape on screen and tweak them without ever touching physical materials. This means catching those pesky design issues long before anyone starts manufacturing something in reality. Companies report saving around 30% on development costs just by using this approach instead of building multiple physical versions. Plus, modern collaboration software lets everyone on the design team jump into the same digital space at once. They can point out problems as they happen, suggest improvements right there, and generally make the whole creative process move much faster than old school methods allowed.

Optimizing cross sections represents an intelligent strategy within aluminum design that delivers significant material savings. When manufacturers refine the geometric structure of extruded parts, they manage to cut down on raw materials while still maintaining strength and functionality requirements. Computer simulations and engineering software now make it possible to test different profiles and configurations until finding the sweet spot between material consumption and structural needs. Some studies indicate around a 10-15% reduction in material waste through these optimized approaches, which makes a tangible difference in production costs and environmental impact over time. For companies focused on sustainability goals, this kind of cross-sectional refinement offers real value across both economic and ecological dimensions.

When manufacturers build features right into aluminum extrusions during production, they cut down on the whole assembly process significantly. Fewer parts need putting together means less chance of something going wrong during assembly, which makes products stronger overall while saving both money and time in the long run. Some studies looking at these integrated designs show around a 20% drop in labor costs for assembly work. For shops working with aluminum specifically, this approach really pays off because it cuts through all the unnecessary complexity. Parts fit better together from the start, so there's less stress on joints and connections when everything comes together at the end of the line.

Custom dies are specialized tools used to shape aluminum into complex geometries during the Aluminum Extrusion process. They are important because they allow for precision in creating intricate profiles that improve efficiency and reduce material waste.

Hollow extrusions are designed with internal voids which make them lighter and serve well for insulation purposes. Solid extrusions, on the other hand, provide greater structural integrity and are used in applications where strength is paramount.

Continuous profiles reduce waste and energy consumption, enhance mechanical properties, and improve production speed and efficiency. This aligns with sustainable manufacturing practices and increases competitiveness.

Aluminum alloys offer high strength while being lightweight, making them ideal for industries that require performance without the burden of excess weight, such as aviation and automotive industries.

Anodizing enhances the corrosion resistance of Aluminum Extrusions by adding a protective oxide layer, thereby extending their lifespan and aesthetic appeal in harsh environments.