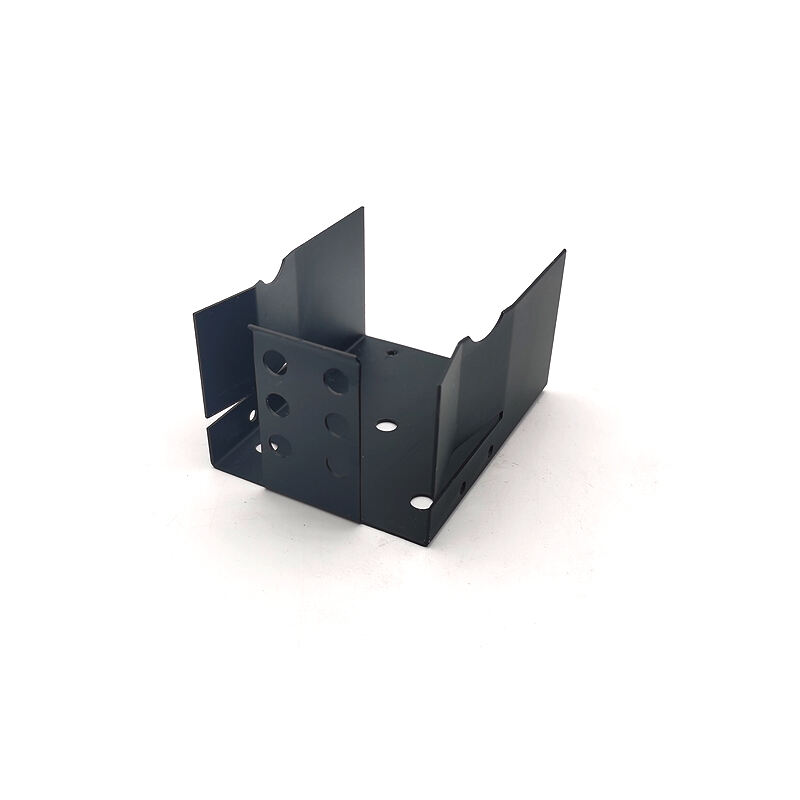

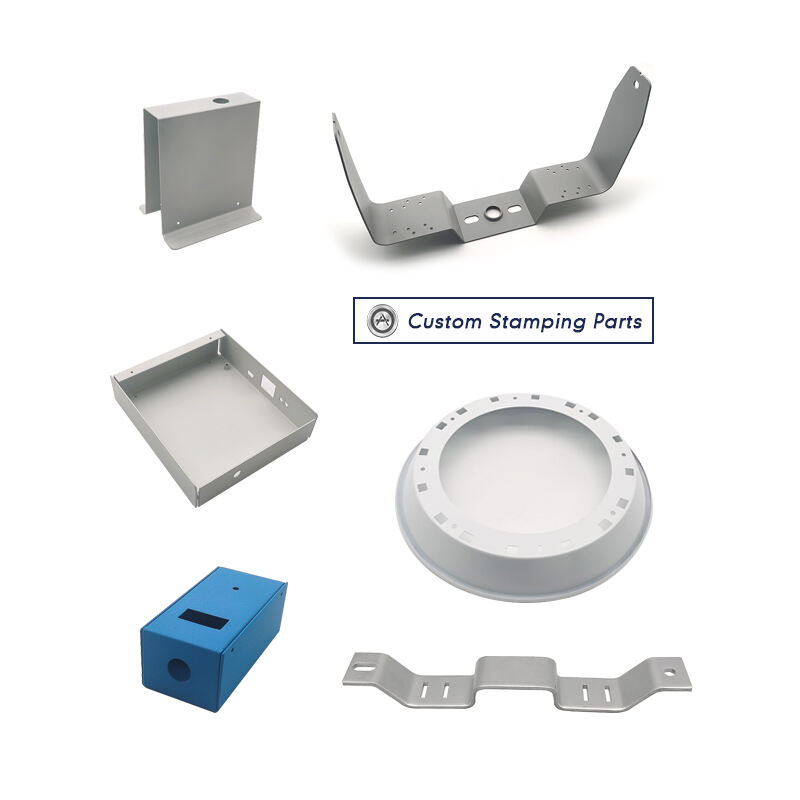

stamping die components

Stamping die components form the essential foundation of modern metal forming processes, comprising precisely engineered elements that work together to create accurate and repeatable parts. These components include the die block, punch, stripper plate, guide pins, and springs, each serving a specific function in the metal stamping process. The die block acts as the base structure, providing stability and support for other components. The punch, designed with exact specifications, creates the desired shape by penetrating the material. Stripper plates hold the material firmly during stamping while facilitating part removal. Guide pins ensure precise alignment between upper and lower die sections, maintaining accuracy throughout production cycles. Springs control the force application and material flow, ensuring consistent results. These components are manufactured using high-grade tool steel, incorporating advanced heat treatment processes to enhance durability and wear resistance. The integration of these elements enables manufacturers to produce complex metal parts efficiently, meeting strict tolerances and quality standards across automotive, aerospace, electronics, and consumer goods industries.