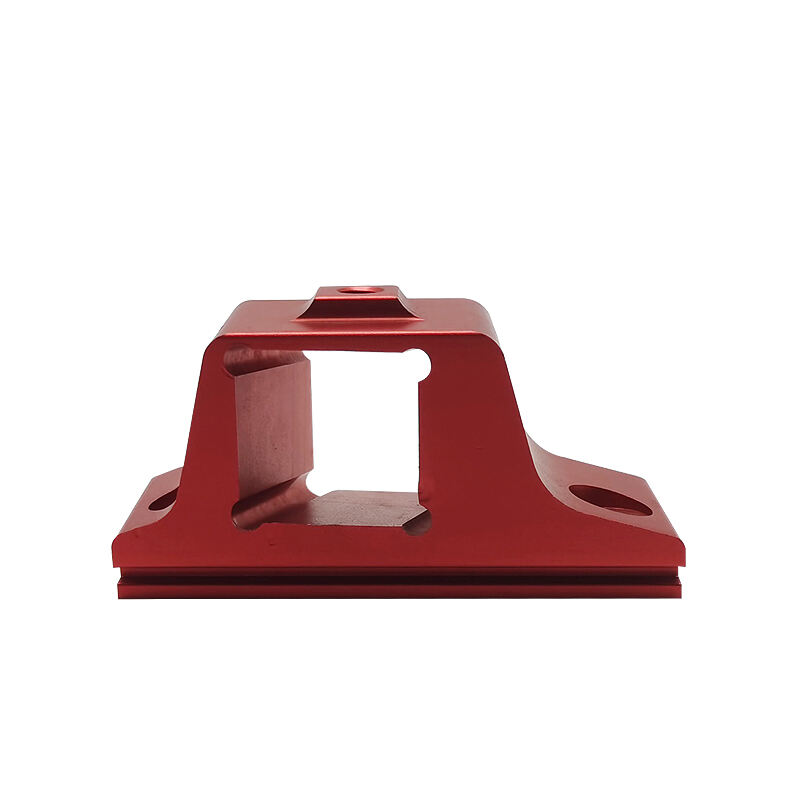

cnc milling parts

CNC milling parts represent a cornerstone of modern precision manufacturing, utilizing computer numerical control technology to create complex components with exceptional accuracy. These parts are produced through a subtractive manufacturing process where automated cutting tools remove material from a workpiece according to programmed specifications. The technology enables the creation of intricate geometries, tight tolerances, and consistent quality across production runs. CNC milling parts can be manufactured from various materials, including metals, plastics, and composites, making them versatile for diverse applications. The process employs multiple axes of movement, allowing for sophisticated 3D shapes and features that would be impossible to achieve through conventional machining methods. These components find extensive use in aerospace, automotive, medical devices, and industrial equipment, where precision and reliability are paramount. The technology incorporates advanced features such as automatic tool changing, real-time monitoring, and quality control systems, ensuring optimal performance and minimal deviation from specifications. CNC milling parts demonstrate remarkable surface finish quality and dimensional accuracy, often achieving tolerances within micrometers.