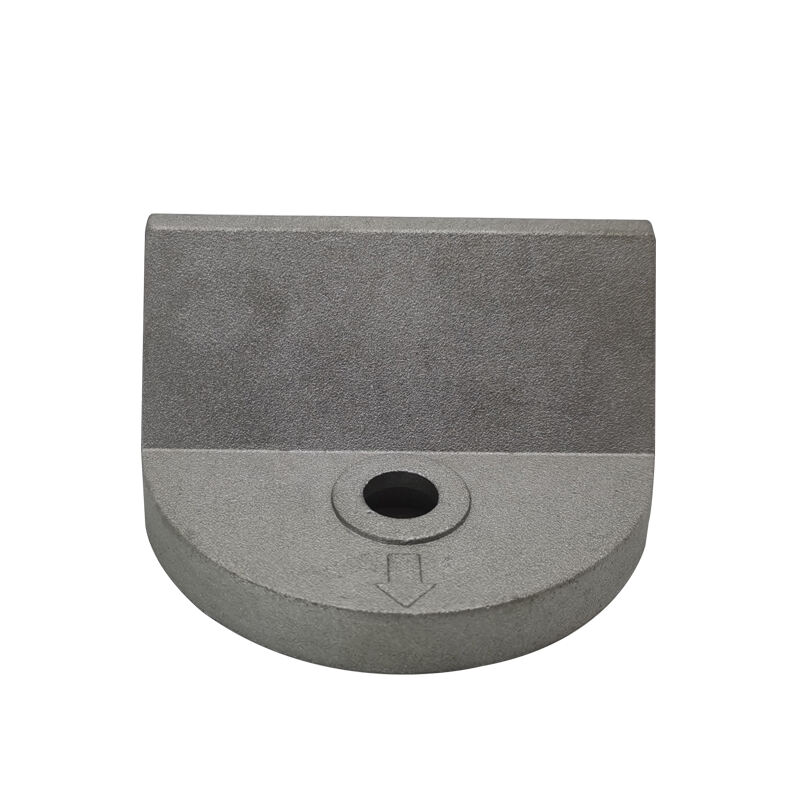

precision castings & machining

Precision castings and machining represent advanced manufacturing processes that combine traditional casting methods with modern machining techniques to produce highly accurate components. This integrated approach delivers exceptional dimensional accuracy, superior surface finishes, and complex geometrical features that meet stringent engineering requirements. The process begins with the creation of precise molds, followed by carefully controlled casting procedures that utilize various metals and alloys. The cast components then undergo sophisticated machining operations using computer numerical control (CNC) technology, ensuring tight tolerances and exceptional repeatability. These processes are particularly valuable in industries requiring high-performance parts, such as aerospace, automotive, medical devices, and industrial equipment manufacturing. The technology enables the production of intricate components with internal passages, uniform wall thickness, and complex curved surfaces that would be difficult or impossible to achieve through conventional manufacturing methods. Modern precision casting and machining facilities employ advanced quality control systems, automated inspection processes, and rigorous testing protocols to maintain consistent product quality and reliability.