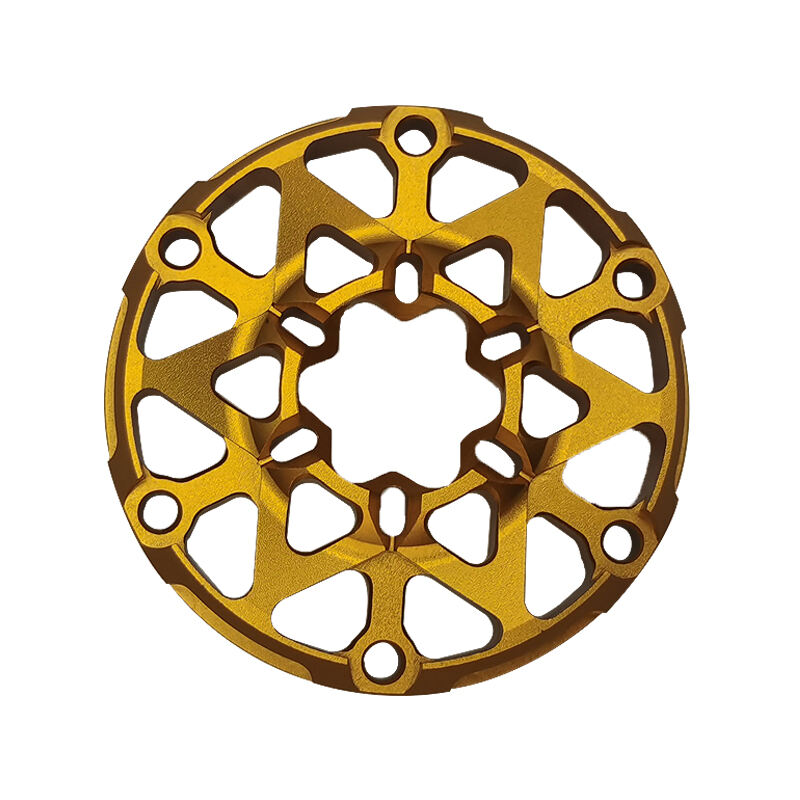

high precision parts

High precision parts represent the pinnacle of manufacturing excellence, embodying exceptional accuracy and consistency in modern industrial production. These components are manufactured to extremely tight tolerances, typically measured in micrometers or even smaller units, ensuring perfect fit and functionality in various applications. The manufacturing process involves advanced CNC machining, precision grinding, and sophisticated quality control systems that utilize state of the art measurement technologies. These parts are essential in industries ranging from aerospace and medical devices to semiconductor manufacturing and automotive systems. The production process integrates cutting edge materials science with advanced manufacturing techniques, ensuring optimal performance under diverse operating conditions. High precision parts are characterized by their superior surface finish, exact dimensioning, and exceptional reliability. They often incorporate special coatings or treatments to enhance durability and reduce friction. The quality control process includes detailed inspection procedures using coordinate measuring machines (CMMs), optical comparators, and other advanced metrology equipment to verify dimensional accuracy and surface characteristics. These components play a crucial role in maintaining the efficiency and reliability of complex mechanical systems, where even minimal deviations could lead to significant performance issues.