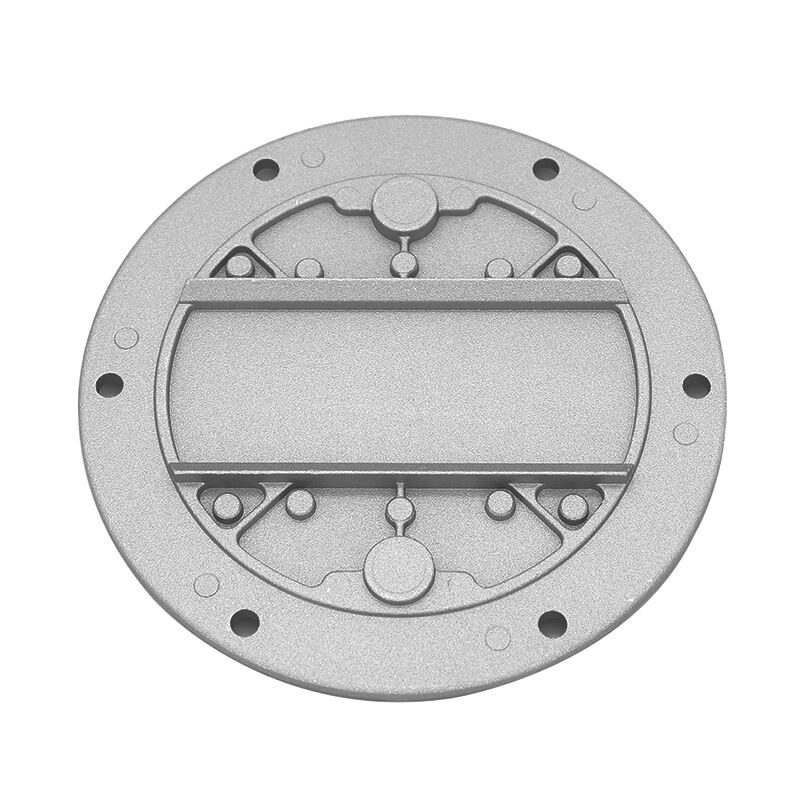

cast aluminum parts

Cast aluminum parts represent a cornerstone in modern manufacturing, offering an optimal blend of durability and versatility. These components are produced through a sophisticated casting process where molten aluminum is poured into precisely engineered molds, allowing for complex geometries and intricate designs. The resulting parts exhibit exceptional strength-to-weight ratios, making them ideal for applications where weight reduction is crucial without compromising structural integrity. The manufacturing process enables the creation of components with uniform wall thickness, excellent surface finish, and precise dimensional accuracy. These parts find extensive use across automotive, aerospace, industrial machinery, and consumer goods sectors. The inherent corrosion resistance of aluminum, combined with the ability to incorporate various alloy compositions, ensures longevity and reliability in diverse operating conditions. Modern casting techniques allow for the integration of features such as internal channels, mounting points, and reinforcement structures directly into the design, reducing the need for secondary operations and assembly costs. The versatility of cast aluminum parts extends to their ability to withstand both high temperatures and extreme weather conditions, while maintaining their structural properties and dimensional stability.